The "Molecular Twin": How Laboratory Synthesis Replicates The Geological Process

Laboratory-grown diamonds represent a technological breakthrough that perfectly replicates nature's geological processes at the atomic level. Through controlled synthesis environments, scientists recreate the intense thermodynamic conditions found deep within Earth's mantle, producing materials that are molecularly identical to naturally formed diamonds. This process eliminates the randomness of geological formation while maintaining the exact same carbon crystal structure, optical properties, and physical characteristics that define genuine diamond material.

The creation of laboratory-grown diamonds involves sophisticated replication of the extreme conditions found hundreds of miles beneath Earth’s surface. Modern synthesis technology recreates the precise temperature and pressure environments that naturally occur in the planet’s mantle over millions of years.

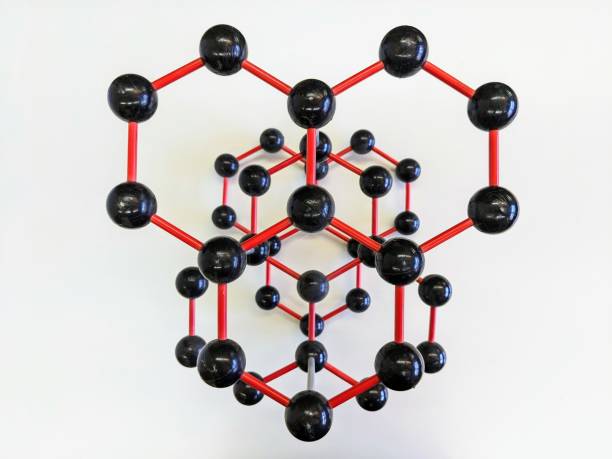

How Atomic Lattice Structure Aligns Perfectly With Natural Carbon Formations

The atomic lattice of laboratory-grown diamonds achieves perfect alignment with natural carbon structures through controlled crystal growth processes. Each carbon atom bonds with four neighboring atoms in the same tetrahedral arrangement found in mined diamonds. The synthesis process maintains the cubic crystal system that defines diamond’s hardness rating of 10 on the Mohs scale. Advanced monitoring systems ensure that the carbon atoms arrange themselves in the identical face-centered cubic structure, creating the same density of 3.52 grams per cubic centimeter found in geological specimens.

How Synthesis Recreates Intense Thermodynamic Conditions of Earth’s Mantle

Laboratory synthesis recreates the intense thermodynamic conditions of Earth’s mantle through two primary methods: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). HPHT chambers generate pressures exceeding 50,000 atmospheres and temperatures reaching 1,500 degrees Celsius, matching the conditions found 100-200 kilometers below Earth’s surface. CVD processes use plasma activation to break down carbon-containing gases at lower pressures, allowing carbon atoms to deposit layer by layer onto seed crystals. Both methods produce the same crystalline structure that forms naturally over geological time periods.

How Optical Refraction Occurs at Identical Velocity Through Both Materials

Optical refraction occurs at the exact same velocity through both laboratory-grown and natural diamonds due to their identical crystal structure and chemical composition. Light travels through both materials at a refractive index of 2.42, creating the same brilliance and fire characteristics. The dispersion rate of 0.044 remains constant regardless of formation origin, producing identical spectral separation when white light passes through the crystal. Professional gemological instruments measure no difference in light behavior between the two categories, as both materials bend light according to the same physical laws governing carbon crystal optics.

How Thermal Conductivity Probes Register Genuine Diamond Properties

Thermal conductivity probes register laboratory-grown diamonds as genuine diamond material without distinction because both share the same exceptional heat transfer properties. Diamond’s thermal conductivity of 2000 watts per meter-kelvin remains consistent across formation methods, making it one of the most efficient heat conductors among natural materials. Professional diamond testers rely on this property to distinguish diamonds from simulants like cubic zirconia or moissanite. The probe technology cannot differentiate between natural and laboratory-grown specimens because the carbon lattice structure responsible for thermal conductivity remains identical.

How Type 2a Classification Represents The Purest Carbon Crystal Form

The classification of Type 2a represents the purest form of carbon crystal, rarely found in traditional mining operations but commonly achieved in laboratory synthesis. Type 2a diamonds contain virtually no nitrogen impurities, less than 5 parts per million, resulting in exceptional optical clarity and colorlessness. Controlled laboratory environments eliminate the nitrogen contamination that affects approximately 98% of mined diamonds, which typically fall into Type 1a or 1b categories. The absence of nitrogen allows for superior light transmission and creates the coveted D-F color grades that command premium valuations in the market.

| Provider | Synthesis Method | Cost Estimation | Production Timeline |

|---|---|---|---|

| Diamond Foundry | CVD Process | $300-800 per carat | 2-4 weeks |

| Pure Grown Diamonds | HPHT Method | $400-900 per carat | 3-5 weeks |

| WD Lab Grown | CVD Technology | $350-750 per carat | 2-3 weeks |

| Lightbox (De Beers) | CVD Process | $800 per carat | 4-6 weeks |

| New Diamond Technology | HPHT Method | $450-1000 per carat | 3-4 weeks |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

How Professional Grading Standards Apply Identically to Both Categories

Leading gemological institutes apply identical grading standards to both laboratory-grown and natural diamonds without bias in their assessment criteria. The Gemological Institute of America (GIA), American Gem Society (AGS), and International Gemological Institute (IGI) evaluate both categories using the same 4Cs framework: cut, color, clarity, and carat weight. Laser inscriptions provide microscopic verification of growth origin, with laboratory-grown stones receiving distinct notations on their certificates. Professional analysis utilizes standard 10x magnification tools to map internal clarity characteristics, measuring the same inclusion types and crystal formations regardless of formation source.

How Digital Analysis Transforms Selection and Acquisition Processes

The selection methodology has transitioned from physical examination counters to high-resolution digital analysis platforms that provide enhanced visibility into diamond characteristics. Database filtering systems isolate specific cut proportions and clarity grades across global inventory networks rather than limiting choices to local display cases. High-definition imaging reveals internal details often invisible to naked eye examination, allowing consumers to evaluate diamonds from multiple facilities simultaneously. The acquisition process concludes with secure logistical transfer protocols that ensure proper handling and delivery from production facilities to end users.

Laboratory synthesis has achieved molecular-level replication of natural diamond formation, creating materials that share identical physical, optical, and chemical properties with their geological counterparts. The controlled production environment eliminates many variables associated with mining while maintaining the fundamental characteristics that define diamond as a material.