The "Molecular Twin": How Laboratory Synthesis Duplicates The Geological Process

Laboratory-grown diamond is not a look‑alike; it is the same carbon crystal built under controlled extremes that mirror the Earth’s mantle. For Canadian readers, this means the stone’s structure, optics, and measurable performance match mined counterparts while documentation, laser inscriptions, and digital selection tools bring unusual clarity to purchase decisions.

Laboratory synthesis has made it possible to reproduce the conditions that build diamond in nature and to guide that process with precision. In place of geological timescales and volcanic transport, technicians initiate crystal growth on a tiny carbon seed, then sustain the required pressure, temperature, and chemistry for weeks. The outcome is a diamond whose atomic arrangement, optical behaviour, and measurable thermal response are indistinguishable from stones formed deep underground. This is why many materials scientists describe it as a molecular twin: a carbon lattice with the same composition and properties, produced by different routes but verified through the same professional standards and instruments in Canada and elsewhere.

Atomic lattice and optical parity

At the heart of the claim is the lattice itself. The atomic lattice of a laboratory‑grown diamond matches the tetrahedral carbon network found in natural diamond, yielding the same crystal symmetry and spacing. Because the structure is the same, light experiences the same refractive index, so optical refraction occurs at the same velocity through both materials when measured under identical conditions. Diamond testers that use thermal conductivity or combined conductivity/thermoelectric probes register lab‑grown surfaces as genuine diamond without distinction, reflecting the shared physics rather than any marketing label. In other words, what reaches your eye is not a visual simulation or synthetic imitation but the performance of a material twin.

Type IIa purity and lattice integrity

Classification helps explain why many lab‑grown diamonds exhibit exceptional clarity. Type IIa represents an extremely low‑nitrogen carbon crystal, a category rarely found in mining. In a controlled growth environment, the inflow of nitrogen is minimized, which sharply reduces the impurities common in traditional stones and the colour they can introduce. Without the chaotic pressures and temperature swings of volcanic ascent, the structure can develop with fewer stress patterns than some mined crystals, though lab‑grown stones have their own growth signatures. The visual output often reaches colourless tiers of transparency when growth conditions are tuned accordingly, and the material integrity tends to be more consistent than the random quality distribution associated with geological extraction.

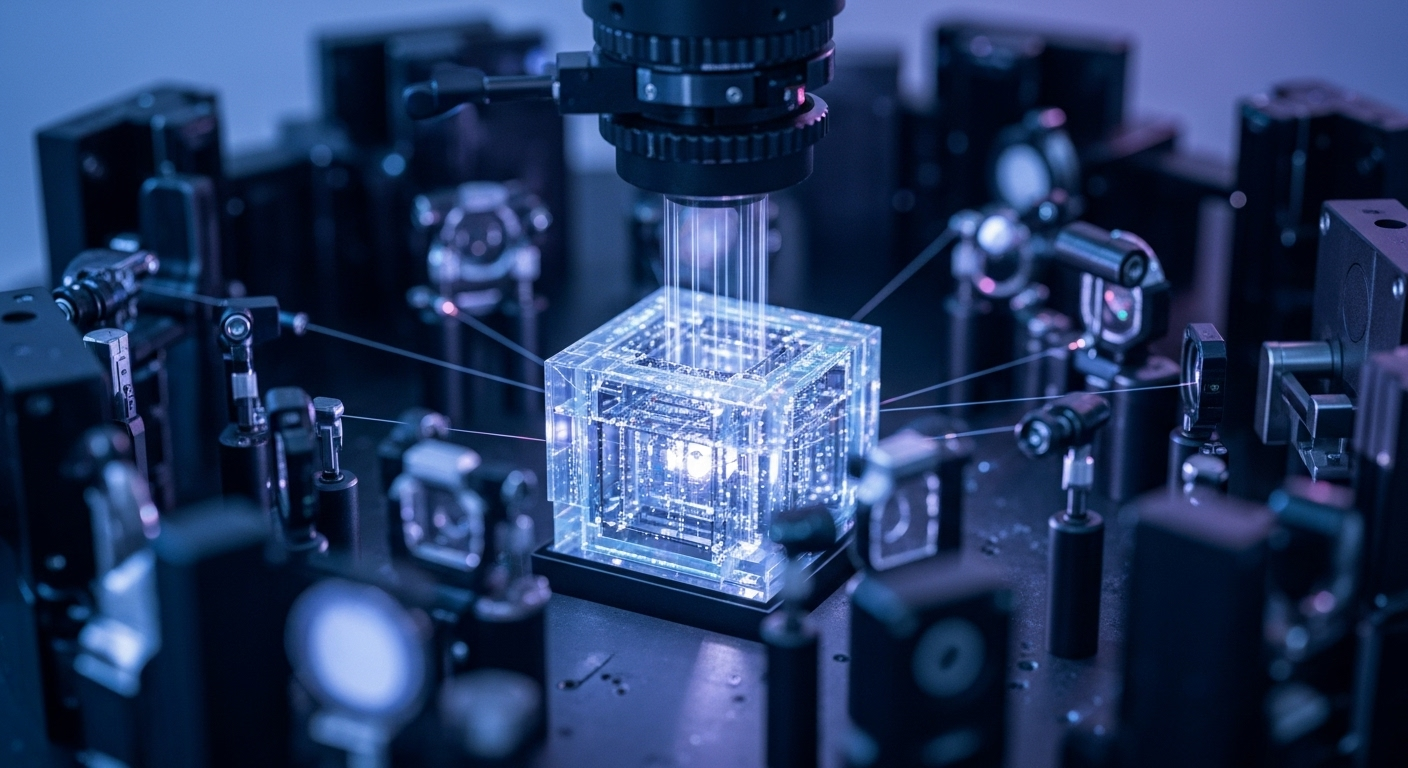

Recreating mantle conditions in the lab

Two primary methods parallel the mantle’s thermodynamics. High Pressure High Temperature (HPHT) compresses carbon to gigapascal‑range pressures while heating it to well above 1,300°C, allowing atoms to assemble into diamond on a seed. Chemical Vapour Deposition (CVD) activates carbon‑rich gases in a plasma, depositing carbon atom by atom onto a seed at carefully controlled temperatures and pressures. In both routes, the synthesis process recreates the intense thermodynamic conditions of the Earth’s mantle in a monitored chamber. What nature performs over eons is compressed into a production timeline of weeks, with sensors tracking parameters so crystal growth proceeds within a stable window for size, colour, and clarity objectives.

Supply chain and quality control focus

Because crystals originate in reactors rather than ore bodies, the supply chain bypasses heavy industrial excavation and long‑distance ore transport. The distribution network often connects growth reactors directly to cutting and polishing facilities, limiting the need for intermediary aggregators. Quality control protocols can focus exclusively on structural integrity and optical uniformity of the crystal: screening for strain, mapping inclusions, and refining colour before the stone is released for cutting. In market terms, the trajectory increasingly favours technological efficiency—repeatable process control and data‑driven yield—over the logistical complexity of traditional extraction, while maintaining clear disclosure of origin throughout Canadian retail channels.

Certification, laser IDs, and disclosure

Certification protocols rely on standardized optical and dimensional criteria to document material properties regardless of formation source. Reputable laboratories evaluate the 4Cs, fluorescence, and other metrics under controlled lighting and magnification, then record exact physical dimensions and optical performance. Laser inscriptions on the girdle provide microscopic verification of the specific growth origin and report number, enabling traceability through the life of the stone. Professional analysis uses standard magnification tools to map internal clarity characteristics and growth features, and regulatory definitions in trade standards recognize the shared chemical composition of diamond whether mined or lab‑grown, alongside a requirement for accurate and conspicuous disclosure to consumers in Canada.

Digital selection and secure delivery

Selection has shifted from glass cases to high‑resolution digital analysis. Instead of choosing only from what a local counter displays, database filtering lets you isolate specific cut proportions, clarity grades, and dimensions across global inventories in real time. High‑definition imaging and 360‑degree video reveal internal details often invisible to the naked eye, while inclusion maps and performance metrics help compare candidates with consistency. Once chosen, the acquisition process concludes with secure logistical transfer from the facility to the end user—insured shipping, tamper‑evident packaging, and a documented chain of custody—so the stone that arrives in Canada matches the digital record reviewed during selection.

In sum, laboratory synthesis duplicates the geological recipe at the level that matters most: atomic structure and measurable properties. With mantle‑like conditions reproduced in controlled chambers, the resulting diamonds meet the same optical and thermal benchmarks as their natural counterparts. Combined with tighter quality control, transparent certification, and modern digital tools, the molecular twin concept reflects material reality rather than metaphor.